The second step of producing oil filters

Step two:

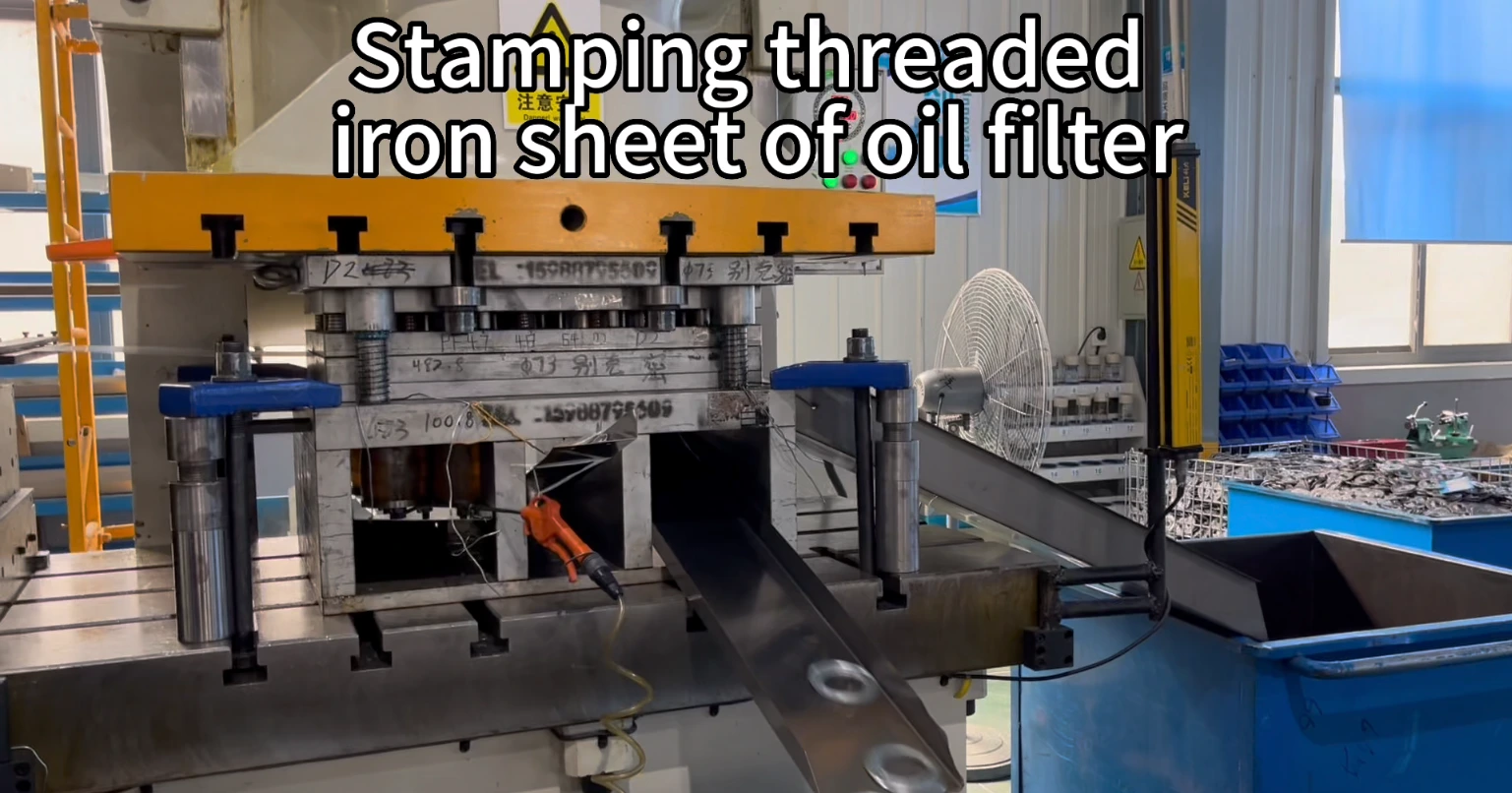

Stamping threaded iron sheet of oil filter

The second step of producing oil filters: Stamping the Cut Sheets

Stamping involves blanking steel sheets, extracting the outer casing, stamping the base plate and end cap of the filter element, and making most of the metallic parts of the filter.

To produce the various metal parts of the filter continuously, we use an automatic press punching machine with high speed and stability.

To meet the needs of a variety of production types, we have more than a dozen 50-200T Punching Machines.

a.Making the Oil Filter Housing/Canister

The oil filter housing is made out of a circular steel sheet which is stamped 1-2 times depending on the size and requirements of the product. After the rough molding process, excess metal is cut off for a clean body.

The last process to make the canister is painting and printing it according to customer requirements. Painting is done not only to improve the visual appearance, but it also plays a role in rust prevention.

b.Filter Base Plate Making

There are two parts to the base plate: a tapping plate and a bottom ring. After stamping, the tapping plate needs to be threaded in an automatic threading machine. Then, it is welded together with the bottom ring in an automatic spot welder.

c.Making Filter Element End Caps

The filter element end caps are stamped and made using an automatic punching machine.

d.Making the Filter Bypass Valve

In order to rivet the bypass valve to the bottom end caps of the filter element, a worker places the die, spring, and bottom end caps in an automatic riveting machine. The machine rivets the lower end caps.

e.Making the Center Tube

After cutting the sheet metal into the specified size, a second machine perforates the tin-plated steel sheets and rolls them into tubes. In the next stage of the filter making process, these center tubes will be inserted into the pleated paper core and ready for use.

QUICK LINKS

Products

If you have any question,please contact us.

Fax: +86-20-3676 0028

Tel: +86-20-3626 9868

Mob: +86-186 6608 3597

QQ: 2355317461

E-mail: 2355317461@jffilters.com